The world’s largest ceramic manufacturer continues to add to its dinnerware producing capacity.

The gradual process of doubling output capacity at RAK Porcelain has now reached completion following the purchase of a Sacmi TKA 240/88,2 roller kiln for firing glazed products (equipped with relative automatic handling) and a Sacmi/Sama 2-head isostatic press mod. LPP-2S-38 for the dry pressing of plates and bowls (equipped with Sacmi/Sama automatic finishing units mod. OFM for non-round articles).

In the recent past, RAK had already purchased and installed an automatic cup-making machine and two pressure casting benches for large trays and plates: these too were supplied by Sama/Sacmi.The existing ‘biscuit’ kiln has, instead, been modernised to allow two-tier firing.

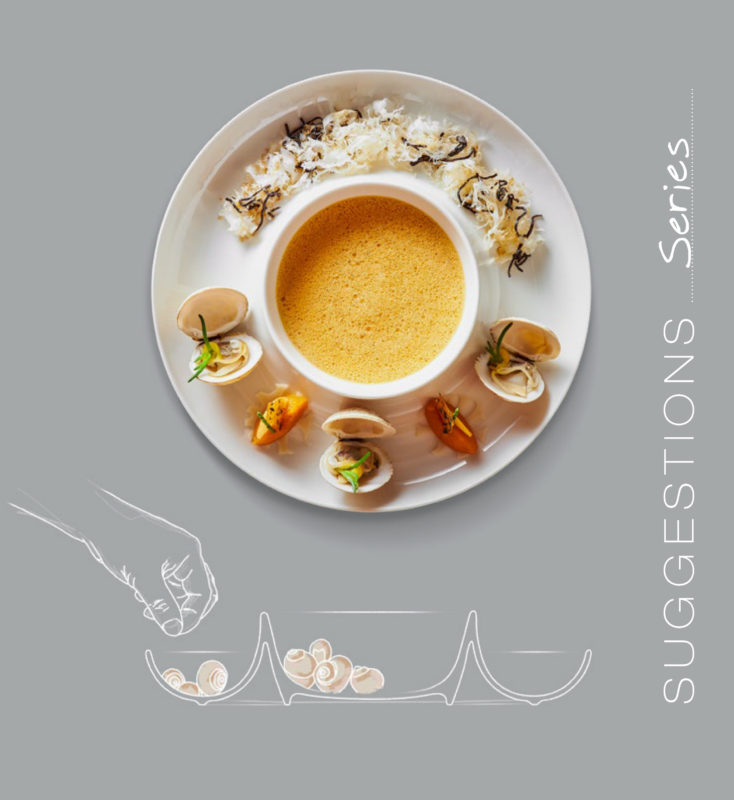

According to Sacmi, it is thanks to the extraordinary efficiency of the technology adopted by RAK Porcelain, their highly qualified personnel and the outstanding reliability of their machines, that output has been boosted while maximising control of both production efficiency and the first-rate product quality that is making ever-larger gains on the luxury tableware market.

To learn more about RAK Porcelain and their wide range of products for the hospitality tabletop industry, go here:

http://www.rakporcelain.eu/