TabletopJournal was fortunate to be able to spend a few minutes with Mepra family member and Sales Manager for North America, Luca Prandelli at this year’s NRA Show in Chicago. Mepra has a wide variety of products, such as this glass table oil & vinegar set, to enhance the guest dining experience Since 1947, Italy’s Mepra has been on a mission to design and manufacture flatware, holloware, and serveware using only the finest materials and finishing techniques. With over sixty years of professional foodservice industry experience, coupled with modern utilitarian design, Mepra offers a complete range of innovative and contemporary products that are in step with the latest trends. We recently got the opportunity to spend a few minutes with Mepra’s Luca Prandelli and ask him a few questions about his family company and its design-driven products.

TabletopJournal: We know that MEPRA is a company that was started by the Prandelli family some time ago. Can you give us a little of the history and is the company still owned and run by your family?

Luca Prandelli: The three Prandelli brothers, Bortolo, Francesco and Giovanbattista, built the first factory in 1901, directly beside the river in Lumezzane, Italy. This allowed them to run machinery by use of a water mill. They worked metals as subcontractors and as primary manufacturers during the 30’s and World War II. After the war, it was necessary to reconvert their production and the three sons of Giovanbattista founded Mepra in 1947.

Mepra stands for “Metallurgica Prandelli” and its founders were the three brothers Pietro, Felice and Giacomo. They built a new and modernized plant in the upper side of the valley to produce aluminum and brass flatware. These raw materials were available in great quantities after the war. Each of the three brothers was responsible for a different function: Giacomo for the production, Felice for the sales, and Pietro, who was previously a school teacher, for accounting. In 1950 the Prandelli brothers decided to convert the production to 18/10 stainless steel. This move was highly successful. In the following twenty years, the company grew continuously and extended the range to include holloware and kitchenware. Later, Mepra also began producing silverplated flatware and holloware. In 1972, Gianni, the son of Pietro, joined the family business. At the beginning, he was responsible for production, together with uncle Giacomo. In the following years, he became the main conduit between production and sales. He became CEO in 1977 and President in 1999. In 1985, Luigi, the son of Felice, joined the company. He was responsible for Marketing and Accounting, and then became CEO. He has also created numerous new successful products and collections. The 80’s were years of great growth for Mepra. For the new collections, stainless steel became combined with new materials such as plastic, glass, wood and porcelain. The sale results were so good that, in 1992, Mepra decided to open a new plant dedicated solely to the production of plastic.

In the 90’s, in order to respond to the most refined customer’s needs, Mepra developed a network of cooperation with some of the most influential designers including Angelo Mangiarotti and a host of other young talented avant-garde designers who still work for the company full-time or on a project basis.

Today, Research and Development costs represent about 8% of the turnover – one of the highest ratios in our industry. This investment spawns creativity, design and utmost quality in everything we do. From the quality of the raw materials we use, to the thickness to the flawless finishing these are all signatures of Mepra.

And, what role do you have in the company’s day-to-day operations?

I joined the family business in 2004 after my university degree in business administration and one year working in the automotive business in United States. It was a short period of time, but I learned a lot about the American market and business environment. As a result my family decided, after a training period in Italy, to give me the responsibility of developing sales in North America. I also take part of the development of new products and marketing together with my father and my cousin, and I’m a member of the board of directors.

TJ: MEPRA does such a fantastic job with metal and the finishes it uses on its metal products. Does the company work in any other material besides metal?

LP: Near Lumezzane, in the city of Gussago, we also have a plastic factory, where we manufacture the resin handles of our iconic flatware Fantasia, available in 37 colors and our unbreakable Polycarbonate drinkware collection

TJ: How does MEPRA view the role of design in product development? And, MEPRA has a history of working with famed designers….is there a specific “type” of design that is the company’s signature?

LP: At Mepra we believe that design should never sacrifice functionality. Our freelance designers always work very close with our internal design team, which makes sure all the products are ergonomic, easy to use and to wash. In fact, we always need to keep in mind that our products, besides being beautiful, need to be functional for our chefs and F&B directors.

A perfect example is our PVD collection of flatware, coated with titanium to become black, gold, bronze, champagne and rainbow. We discovered this technology in 1993, but we didn’t launch the products until 2008. We waited until we were 100% sure, after a lot of research, to be able to offer to our partners a product that was 100% dishwasher safe. For this reason, we are proud to have received many international design awards, including one for all the “Design Plus” for the Ambiente Show in Frankfurt.

TJ: We know that MEPRA has both a consumer line and a hotel & restaurant collection. What role does the hospitality industry play in the company’s business? And, what is the role of each segment within the company?

Retail and Food Service represent each about 50% of our business. Being able to serve both channels allows us to offer a better product to both. In fact many collections are the same and can benefit for being engineered for satisfying both industries.

Hotel and restaurants need products to be durable and resistant and home users are happy to find the same characteristics.

Collections designed for high end design stores and bridal registry stores have aesthetic content that is more and more appreciated by chefs who want to create a distinctive presentation of their food creations.

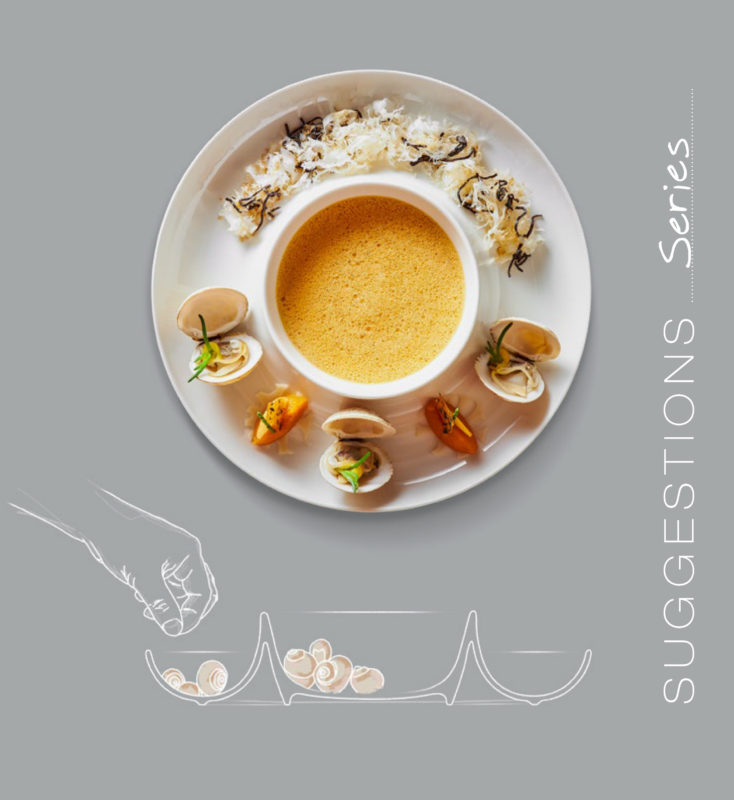

Mepra is well known for its collection of top quality, design-driven, seafood stands. A perfect example of a collection created for the hospitality industry, which has been successful also in retail is our Seafood Stands. The idea behind these items was to place a grill on top of the bowl where the seafood sits in ice.

The concept is simple. Shellfish is placed on ice on the grill allowing ice as it melts to drain right into the base without letting your shrimps or lobsters float in water keeping them fresh and chilled for the guest to enjoy. TJ: Does MEPRA develop products specifically unique for the hospitality industry? And, how might they be different than those that you develop for the consumer?

LP: Although most of the collections are suitable for both markets, there are some products developed specifically for the hospitality industry. A perfect example is our Insulated Plate Set with thermal serving unit. The thermal serving unit is a disc placed in between the plate and the insulated/double wall base and is used to maintain heat or cold.

The disk can be heated in an oven to maintain the temperature of food as it is transported to the guest room. The same concept is applied to keeping salads or any food that needs to be kept chilled where the disk could be placed in the freezer. Temperature, cold or hot can be maintained for about 30 – 40 minutes. The advantage is that food does not continue to cook with open flames that are prevalent in many establishments.

It is able to maintain the food either hot or cold for 30 minutes. This solves the problem of having open flames, or heating boxes. This system reduces operational costs as well as reduces the risk of open flames in hot boxes running through hotel corridors. This thermal system is a safe and efficient alternative to current systems being used in room service and helps also saving on the operations budget.

A few years ago we created a “retail” version of this technology, called Caldo-Freddo (Hot&Cold), which uses a thinner thermal unit, placed between a stainless support and a porcelain container. Mepra metal products are available in a variety of finishes adding to the individuality of the dining experience. TJ: How do MEPRA products change the dining experience for restaurant guests?

LP: Through beauty and functionality. Consuming good food with a beautiful and comfortable tool make the dining experience better and the overall perceived value of the meal higher.

TJ: With MEPRA having so many great products, do you have a personal favorite?

LP: I really like the new champagne flatware. It is a true innovation. In fact, it is as elegant as sterling silver, more durable than silver-plate, but easy to maintain as stainless steel. No need to polish, no need to burnish. No fuss, just easy and elegant, food-safe and dishwasher-safe.

TJ: We know that MIRCENZA is the distribution partner for MEPRA in North America. Are MEPRA products available in all parts of the world?

LP: Yes, our products are appreciated worldwide. We are currently selling in 95 countries. We are proud to portrait with our products Italian tradition, design and lifestyle.

The Mepra design lives on its tradition and the new cutting-edge designs are synonymous with the lifestyle of today’s chefs and homes. Mepra also offers a wide range of serving pieces for buffets. TJ: What trends do you see in flatware and hollowware for the hospitality segment both here in North America and around the globe?

LP: Tabletop in general is becoming less and less a commodity and more and more a tool through which the chef presents his art to his guests. This is true not only for the signature chef, but is becoming a basic requirement for any restaurant.

TJ: With innovation and creativity being major components of MEPRA company DNA, what fun new products should we look forward to from the company in the future?

LP: There are many innovations being tested in our laboratory right now. I’m sure you understand that I prefer not to share them right now. I do not want to create expectations until we are sure the products are ready to be launched and can be guaranteed to be durable and dishwasher safe.

A perfect example is our rainbow finish. We made the first samples 3 years ago, but we launched it officially at NRA last May. The color was originally a production mistake and it took many trials to replicate the process and make the coating stable and dishwasher safe.