Jono Pandolfi produces close to 10,000 pieces of dinnerware a year. It’s easy to assume that Jono is fairly hands-off at this point in his career but he believes otherwise. Referring to himself as a “dinnerware designer and manufacturer,” Pandolfi lies somewhere between a hands-on potter and a small scale factory producer.

Jono studied under Regis Brodie at Skidmore College, then moved on to teaching pottery at the Millbrook School before eventually moving on to New York City, to design jewelry and manage the ceramics studio at Penn South. His pieces are currently used in the Museum of Modern Art’s restaurant, Eleven Madison Park, The NoMad Bar, Clio and the Core Club. He has a dinnerware line called “Kona” sold at Crate and Barrel and also stepped away from the kiln to co-author a book called Spin Fishing Basics, for fishing enthusiasts.

With a resume as packed as his, it’s hard to believe he has time to fire up kilns anymore, but Pandolfi explains that while “we live in a world that expects instant success, like American Idol,” he founded his company on the principals of “one kiln at a time.”

According to Pandolfi, “Deep down, I started as a potter. My passion is firing ware. We’ve grown now that we’re not just a pottery studio, but a dinnerware company. I started one wheel, one kiln and I grew from there. “

He explains that over the years of studying and creating he developed, tweaked, and innovated techniques to help expedite the process so that all the forming could happen without him being there. However he insists on handling all the glazing and stacking of the kilns.

Yet despite the techniques he has developed over the years, Jono does admit that the process of turning raw clay into a finished plate is far from an easy one. “There’s so many checks when we process the clay. We’re checking to make sure there’s no air, we’re rolling out slabs for the jigger to get the right thickness and we’re checking it over 10 times to make sure the quality is there.” You get the idea that the process can be a bit stressful at times.

But for Jono Pandolfi, it’s a labor of love. He re-launched his company, Jono Pandolfi Designs, in 2010 with a stronger understanding and desire to work in the niche table ware market.

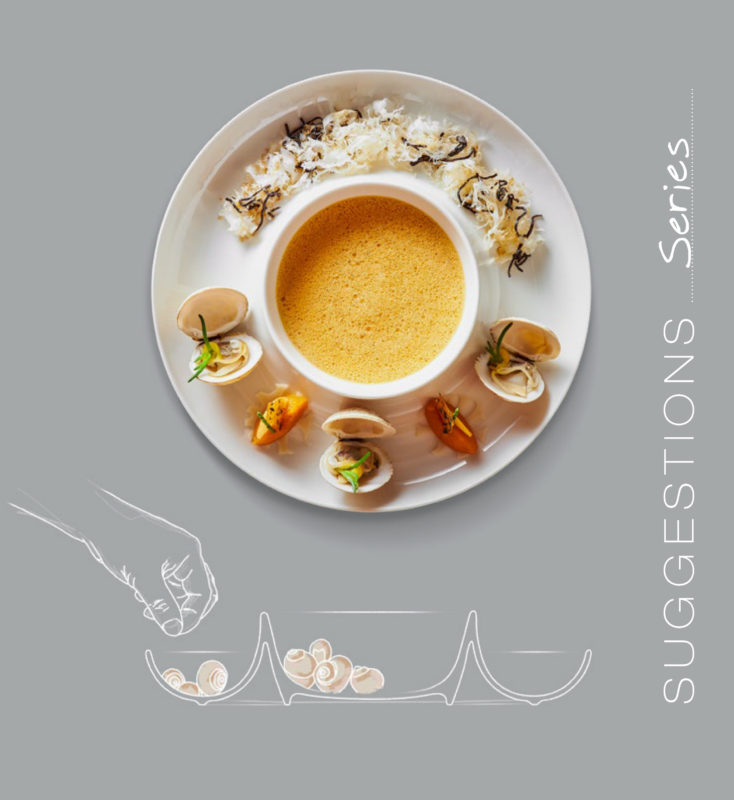

“I gradually learned that I had an interest in tabletop. I made a few clay pieces in high school but it wasn’t until I owned a company that I really loved it,” says Jono. “ I love designing dinnerware for the companies that commission me now. I love giving the diners the chance to notice the tableware. And even though the people I work for want that chic minimal ware, there’s just enough detail for the diner to notice over the stark, white, porcelain.”

He even likens his love and passion to that of the chefs that use his ware. “With all the chefs I’ve worked with, they are passionate about what they do. I want to empower them to serve their food on the kind of plate they want. Why should they dig from the same catalog that all chefs have?”

Overall, Jono Pandolfi realizes the niche his company has. He recognizes that the way he crafts his ware has an impact long after it leaves the kiln and he explains it this way, “You give a chef the opportunity to serve on their own plate, they’re going to want to take the opportunity, and it’s going to enhance what they are doing for their client. They already put so much money in to the interior, the PR, the printing, the uniforms, the ingredients, skills and everyone who attributes to the restaurant. It’s a natural extension to have that go to your dinnerware as well.”

It would appear as though the process never ends.

To learn more about Jono Pandolfi and his company, go here:

http://www.jonopandolfi.com/

By Hamid J. Ali