James Schulze Numerous material choices exist for a foodservice operator purchasing new flatware. A customer can almost feel the need to consult a metallurgist when considering the bewildering amount of information available on flatware with nickel, flatware without nickel, silverplated flatware and more. Manufacturers make numerous product claims and every year introduce new choices of patterns in all materials. To keep it simple, an operator only needs to consider three options – silverplate flatware, flatware with nickel, andflatware without nickel. These three options can be evaluated based on where the flatware is being used, how often it is being used, aesthetic requirements, and budget available.

First, some basic definitions are necessary. Silverplate flatware consists of a base metal “body” with a coating of silver over it. The base metal can be brass, nickel or stainless steel, but most new silverplate flatware has a stainless steel base. The silverplate is applied by soaking the base flatware in a plating tub that is electrically charged causing silver ions to adhere to the metal. Once the silverplate is thick enough, the manufacturer must polish and finish the flatware for packing. Silver thickness is measured in microns. Stainless steel is just as it is described – steel that doesn’t stain due to the addition of at least 10.5% chrome by weight. Flatware manufacturers then can add varying amounts of nickel to the stainless alloy. The nickel allows flatware to keep its luster and shine longer and makes flatware more impervious to rusting and corroding. Generally stainless steel flatware is either 18/0 (18% chrome, 0% nickel) or 18/10 (18% chrome, 10% nickel). There are some additional variations like 21/0 and 18/8, but they perform similar to 18/0 and 18/10, respectively. Silverplate flatware is the most expensive option to consider. The expense is based on material and finishing costs. The silverplating process increases raw material and labor costs in the production hence the higher end price. Silverplate flatware also has the greatest lead-time to deliver and the highest maintenance costs. Most silverplate flatware suppliers plate the flatware to order adding 30 to 60 days to the lead-time.

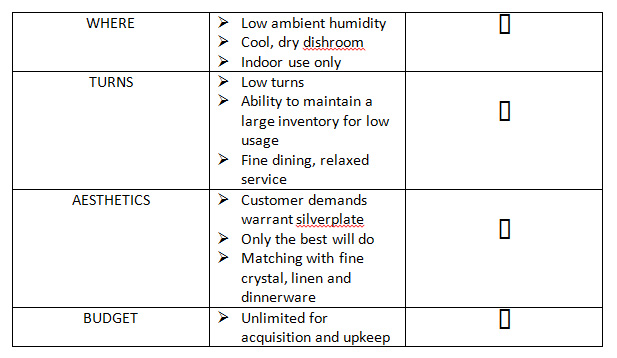

Once sliverplate flatware is in service it must be maintained by burnishing or polishing, again increasing cost of service. Based on the considerations above – where the flatware is being used, how many turns the operator has, aesthetic requirements and budget – silverplate flatware can be evaluated for purchase If the customer can’t “check the boxes” because the conditions noted don’t exist, then it is time to consider stainless steel flatware. New high polish 18/10 flatware has all but taken over the silverplate market. Great quality 18/10 holds a luster much longer than years ago, and doesn’t require the lead-time for delivery, nor does it have high maintenance costs. The downside to 18/10 flatware is the cost of nickel can be quite high. Nickel costs continually escalate thus closing the initial difference in acquisition cost between 18/10 and silverplate.

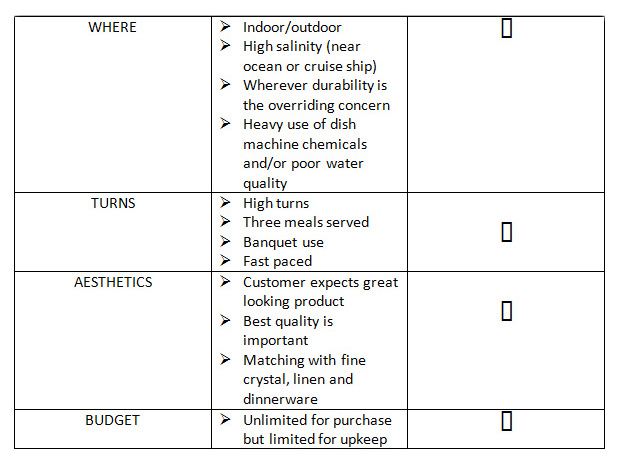

Again, consider the 4 simple caveats when evaluating if 18/10 flatware is the proper choice: If cost is the overriding issue, and the flatware isn’t going to be “abused” in daily service, then 18/0 flatware is a viable option. The most economical choice, and the choice most consumers are making, is to purchase 18/0 flatware, or flatware without nickel. Removing all nickel is the best way to keep cost down. Better quality stainless steel allows 18/0 flatware to keep then shine longer, but it will not perform as well as flatware with nickel. After many washings 18/0 flatware will turn dull, almost to a gunmetal grey. Flatware without nickel also works in a silverware trap, thus keeping product from being thrown away.

Any customer can quickly and easily determine the best flatware to purchase by keeping these simple questions in mind when looking at new flatware. No consumer has “money to burn” so it is important to not overspend, but it is also important to realize the limitations of each material choice.

Making the right decision increases both top line (guest satisfaction) while protecting the bottom line (lowering cost). And, after all….isn’t that the objective?

James Schulze has been in the foodservice industry since 1996 as a manufacturer’s rep, dealer sales rep, and now senior management as President and Chief Operating Officer for Clipper Corporation. Clipper Corporation is a diverse, southern California based company, and a leading supplier of flatware, smallwares and uniforms to chain restaurants. Schulze has spent his career designing and specifying tabletop at all price points to foodservice operators ranging from diners to five star hotels. Schulze has worked closely with fine tableware factories worldwide manufacturing both foodservice and retail tableware.